Quantidade de pedido mínimo:1

Modelo: 4-1

marca: JCB

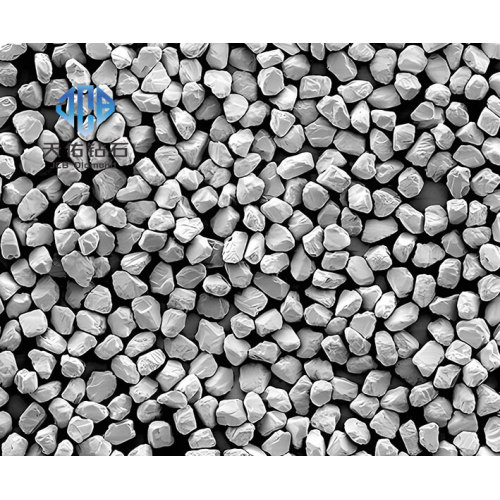

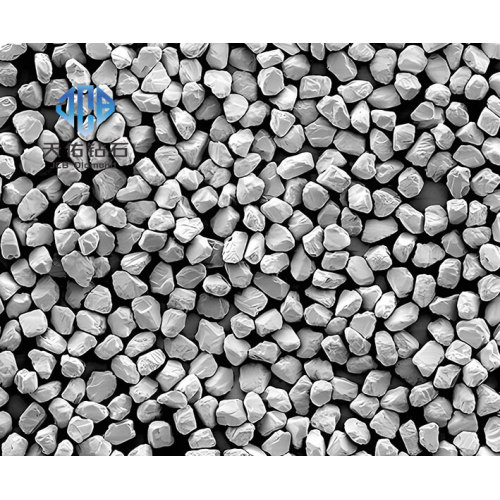

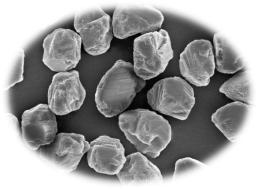

Pó Geral de Diamante Micron (Série JGDM – Abrasivos Versáteis de Diamante Sintético)

O pó de mícron de diamante geral da série JCB JGDM é um abrasivo de diamante sintético acessível e de alto desempenho. É usado para muitos trabalhos de retificação, lapidação e polimento. Feito de cristais de diamante cultivados em laboratório de alta qualidade, este pó é cuidadosamente selecionado e tem bordas afiadas, boa resistência ao calor e formato de partícula uniforme.

Saiba mais: https://en.jcbdiamond.com/

Principais recursos

Formas em bloco ou semi-bloco, equilibrando força e nitidez

Desempenho de corte estável com boa autoafiação

Controle rígido de tamanho, disponível de 0–0,25 μm a 40–60 μm

Alta resistência ao calor e a produtos químicos, funciona em moagem úmida ou seca

Funciona com diferentes métodos de colagem, como resina, metal e ligações galvanizadas

Aplicativos

Retificação e polimento de carboneto de tungstênio, cerâmica, pedra, vidro óptico e ligas duras

Ferramentas diamantadas com resina : enchimento para rebolos e segmentos

Pastas e pastas de diamante: para polimento de precisão em semicondutores, lentes e discos rígidos

Fabricação de ferramentas: material base para sinterização de PCD e materiais superduros

Acabamento superficial geral: usado para selos mecânicos, peças de moldes e componentes aeroespaciais

|

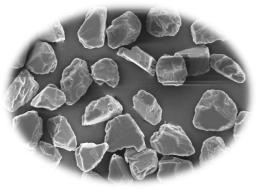

ACM Features: Utilizes premium resin-bonded diamond JBD6(AC6) as raw material, processed through advanced manufacturing techniques including crushing, shaping, purification, and grading. The product is light gray, has a regular crystalline shape, low impurity content, low magnetism, excellent self-sharpening properties, a polycrystalline-like structure, and precise control over shape and particle size distribution. Applications: Suitable for the production of resin-bonded abrasives, grinding pastes, and grinding fluids, used in precision polishing of hard alloys, optical glass, and areas requiring extremely high product quality. |

|

JGDM-D Features: Made from high-quality resin-bonded diamond JRD, processed through advanced manufacturing methods involving crushing, shaping, purification, and grading. The product is light yellow-green, has a relatively regular crystal shape, low impurity content, good self-sharpening properties, and uniform particle size distribution. Applications: Ideal for resin-bonded, ceramic-bonded abrasives, grinding pastes, and fluids. Used in polishing gemstones, stone, ceramic tiles, glass, optical glass, and hard alloys. An economical resin diamond micro powder with high grinding efficiency and wear resistance. |

|

JGDM-C Features: A general-purpose powder, made from high-quality single-crystal synthetic diamond JSD10. Processed using advanced technology, including crushing, shaping, purification, and grading. The product is light yellow, has a relatively regular crystal form, low impurity content, low magnetism, and even particle size distribution. Applications: Suited for metal-bonded, ceramic-bonded, and resin-bonded abrasives, grinding pastes, and fluids. Used in polishing gemstones, glass, optical glass, ceramics, stone, PCD/PCBN, and other non-metallic materials. |

|

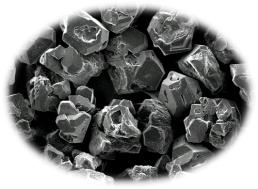

JGDM-B Features: A high-strength powder, made from premium single-crystal diamond JSD20. Processed through advanced techniques involving crushing, shaping, purification, and grading. The product is light yellow, has a regular crystal shape, low impurity content, low magnetism, and a concentrated particle size distribution. Applications: For metal-bonded, ceramic-bonded abrasives, electroplated tools, grinding pastes, and fluids. Used in the production of precision grinding wheels for optical glass, fine grinding pellets, edge grinding wheels, precision polishing discs, sapphire precision grinding wheels for silicon materials, precision processing tools for gems and jade, and wire saws for slicing monocrystalline silicon and sapphire. |

|

JGDM-A Features: A high-strength powder, made from high-strength premium single-crystal diamond JSD30. Processed through advanced manufacturing techniques including crushing, shaping, purification, and grading. The product is light yellow, has a regular crystal shape, extremely low impurity content, low magnetism, a concentrated particle size distribution, high strength, excellent dispersion, and wear resistance. Applications: Suitable for metal-bonded tools, ceramic-bonded tools, and various electroplated tools. Used in cutting, grinding, and polishing of organic and inorganic brittle materials. Applications include wire saws for slicing monocrystalline silicon and sapphire, precision cutting blades for gems and semiconductors, as well as precision grinding and polishing tools for single crystal silicon, polysilicon, diamonds, gems, sapphires, quartz wafers, LED sapphire substrates, liquid crystal glass, high-precision magnetic materials, semiconductors, and other advanced materials. |