Quantidade de pedido mínimo:1

Modelo: 2-1

marca: JCB

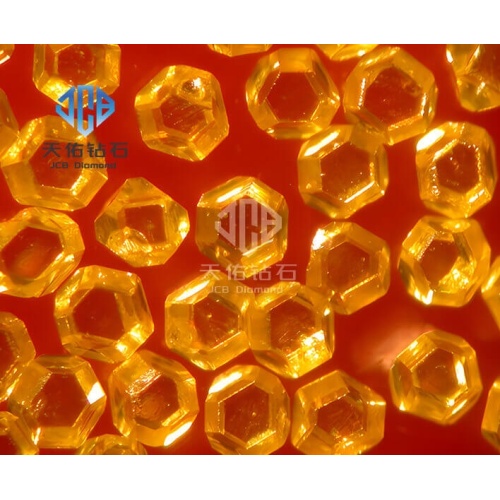

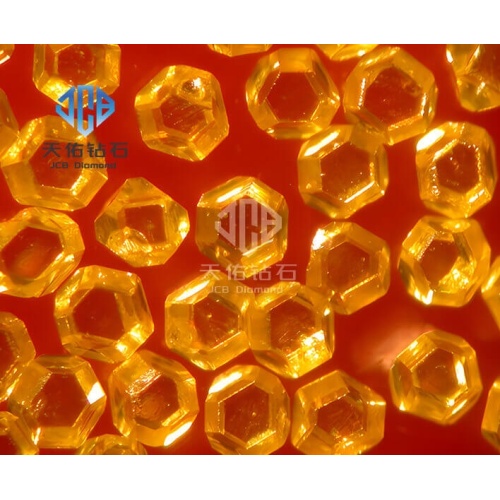

Diamante sintético grosso - série JSD

Os diamantes sintéticos grossos da série JCB JSD são feitos para trabalhos pesados que precisam de alta resistência e durabilidade de desgaste. Eles vêm em tamanhos de grãos de 20/25 a 50/60, têm uma cor dourada-amarela, uma forma de cristal completa, muito poucas impurezas e boa clareza. Esses diamantes oferecem alta resistência, resistência ao impacto e estabilidade de calor, tornando -os ideais para usos industriais difíceis.

Saiba mais : https://en.jcbdiamond.com/

Alta força estática: lida com a pressão extrema

Resistência de impacto: não quebra quando atingido

Estabilidade térmica: funciona bem mesmo quando quente

Baixa impureza: alta clareza, funciona melhor

Resistência ao desgaste: dura muito em empregos difíceis

Ferramentas de corte de diamantes : para corte, moagem e polimento de materiais duros, como pedra, concreto e cerâmica

Ferramentas de perfuração geológica : Ótimo para perfuração de alto desempenho em condições difíceis

SAWS e Equipamento de perfuração : usado em lâminas de serra de diamante, serras de arame e brocas

Ferramentas de soldagem : bom para brasagem e soldagem onde é necessária alta resistência ao calor

Construção e mineração : ideal para cortar concreto armado, asfalto e granito duro

A série JSD é amplamente utilizada no processamento de pedra, perfuração, construção e mineração de petróleo e gás. Suas características fortes tornam -as uma escolha de melhor para trabalhos que precisam de alta dureza, resistência ao desgaste e estabilidade do calor.

JCB JSD Diamantes de cristal único sintético variam em tamanho 20/25 a 50/60. Eles têm uma cor amarela dourada, estrutura limpa, alta clareza e oferecem forte desempenho sob pressão, impacto e calor. Eles são usados principalmente para fazer lâminas de serra de diamante, serras de arame, exercícios de parede fina, ferramentas de moagem, brocas e ferramentas de brasagem. Esses diamantes são comumente usados no trabalho de pedra, corte de concreto, construção de estradas e pontes, processamento de vidro, perfuração de óleo e usinagem mecânica.

|

JSD90

Features: Complete and regular hexoctahedral crystal structure, almost no impurities within the crystal, extremely high static strength (Newton), impact toughness (TI), and thermal stability (TTI). Comprehensive performance meets international standards, with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, and brazing tools under extremely high working intensity conditions, such as cutting and drilling high-strength reinforced concrete, asphalt pavement, and extremely hard granite (F=20), as well as high-performance geological engineering drill bits. |

|

JSD80 Features: Complete and regular hexoctahedral crystal structure, very few impurities within the crystal, high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under high working intensity conditions, such as cutting and drilling reinforced concrete, hard granite (F=15), and high-hardness ceramic materials, as well as engineering drill bits. |

|

JSD70 Features: Relatively complete hexoctahedral crystal structure, few impurities within the crystal, relatively high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with good wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under relatively high working intensity conditions, such as cutting and drilling concrete, hard granite (F=10), high-grade tiles, and high-hardness refractory materials, as well as heavy-duty grinding tools and medium-to-high-load electroplating brazing tools. |

|

JSD60 Features: Relatively complete hexoctahedral crystal structure, relatively few impurities within the crystal, moderate static strength (Newton), impact toughness (TI), and thermal stability (TTI), with a balance of wear resistance and sharpness. Applications: Suitable for high-speed cutting and drilling under medium working intensity conditions, such as cutting and drilling non-reinforced cement pavement, hard marble, low-hardness granite (F=8), large quantities of building materials, refractory materials, and non-ferrous metal materials, as well as heavy-duty grinding tools and medium-load electroplating brazing tools. |

|

JSD50 Features: Relatively regular hexoctahedral crystal structure, moderate impurities within the crystal, average static strength (Newton), impact toughness (TI), and thermal stability (TTI), with moderate wear resistance and good sharpness. Applications: Suitable for high-speed cutting and drilling under medium-to-low working intensity conditions, such as cutting and drilling soft marble and sandstone (F=6-5), glass, ceramics, and batch building materials, as well as medium-load grinding tools and medium-to-low-load electroplating tools. |

|

JSD40 Features: 90-95% regular crystal structure, moderate impurities within the crystal, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with average wear resistance and excellent sharpness. Applications: Suitable for high-speed cutting and drilling under low working intensity conditions, such as small-diameter free-cutting drilling tools, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

|

JSD30 Features: 85% regular crystal structure, more impurities within the crystal compared to JSD40, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and excellent sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, such as cutting and drilling gemstones, jade, crystal, and other high-brittle materials, as well as small batches of stone, glass, and tiles, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

|

JSD20 Features: 70% regular crystal structure, relatively high impurities within the crystal, rough surface, low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and extremely high sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, medium-to-high-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |

|

JSD10 Features: 50% regular crystal structure, high impurities within the crystal, rough surface, very low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with very poor wear resistance, extremely high sharpness, and good self-sharpening properties. Applications: Suitable for medium-to-high-load resin bond tools, medium-to-low-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |